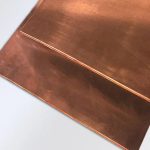

C85200 is a high-performance leaded brass sheet renowned for its exceptional overall performance. Its most prominent feature is its exceptional machinability, thanks to the specific addition of lead to its chemical composition. This allows for easy chip breaking and a smooth surface finish when machining on high-speed automated machine tools. It also significantly protects tool life, extending tool life. This earned it the nickname “free-cutting brass,” making it ideal for the large-scale production of precision parts.

In addition to its excellent machinability, this material maintains excellent strength, hardness, and wear resistance, meeting the essential mechanical requirements for structural components. Furthermore, it inherits the inherently excellent thermal conductivity and corrosion resistance of copper alloys, effectively resisting corrosion from a variety of media, including air and seawater, ensuring long-term stability and reliability in complex environments. These properties make it an ideal material for manufacturing products such as gears, valves, pipe fittings, hardware accessories, and watch components.

| Properties | Metric | Imperial |

|---|---|---|

| Hardness, Brinell | 45 | 45 |

| Tensile strength | 260 MPa | 37700 psi |

| Yield strength (@strain 0.500%) | 90.0 MPa | 13100 psi |

| Elongation at break (In 50 mm) | 35.00% | 35.00% |

| Machinability (UNS C36000 (free-cutting brass) = 100) | 80 | 80 |

| Poisson’s ratio | 0.34 | 0.34 |

| Elastic modulus | 117 GPa | 16969 ksi |